Cable fire coating is successfully developed by our company according to Ministry of Public Security GA181-1998 standard of the new fire-resistant coating , the product added by the tertiary water-based acrylic emulsion materials of various fire retardants , plasticizers and other components, is currently more advanced wire and cable special water-based fire retardant paint . This product coatings when exposed to fire can generate uniform and dense sponge-like foam insulation, can effectively inhibit the barrier of flame propagation and spread of wires, cables play a protective role . Its main advantages are: environmental protection , pollution-free , non-toxic , tasteless , applied to health personnel not pose a threat . This product also has a thin coating, adhesion, flexibility and good features , and has good insulation , corrosion function.

The products are widely used in power plants , mining , telecommunications and civil retardant wire and cable processing , can also be used for fire protection wooden structure , the metal structure of the building and underground engineering combustible substrate and other objects.

Cable fire coating application methods: a front surface of the cable should be fire-resistant coating cable construction dust , oil, debris and other cleaning , polishing and clean before the construction of fire-resistant coating upon the surface is dry . 2 cable construction using fire retardant paint spraying, brushing and other methods should be used to stir, when the paint is slightly thick, the amount of water available for dilution to facilitate spraying is appropriate. 3 When the construction process and before the coating is dry , should be waterproof , anti- exposure, anti-pollution , anti- mobile , anti- bending , promptly repair any damage . 4 For plastics, rubber sheath wire and cable, usually more than five times the direct brushing , coating thickness of 0.5-1mm, about the amount of 1.5kg/m2, greaseproof paper for packaging insulated cable , should be wrapped in a layer of glass cloth , then brushing , if construction in the outdoor or wet environments , should be added to complete the finishing varnish .

Cable fire retardant coating packaging and transportation : a cable fire coating of metal or plastic drums . 2 cable fire retardant paint should be stored in a cool , dry, ventilated environment. 3 When the product transport , should prevent sun, rain , preventing damage to drums , dumping , spilling . 4 cable fire coating effective storage period is one year.

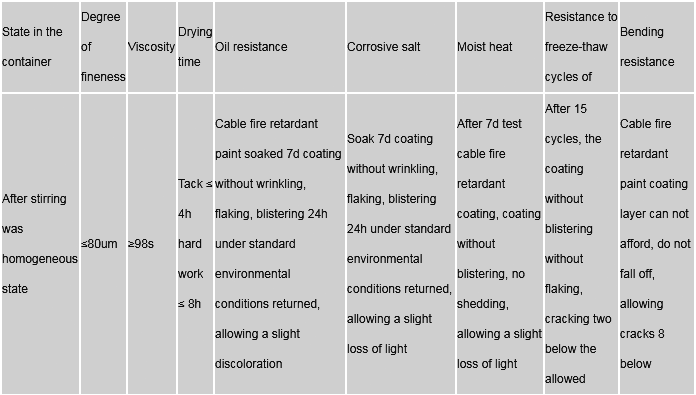

● cable fire performance coatings

Cable fire retardant coating Alerts

! Cable fire retardant coating products have a unified, scientific research and product standards to guide these products, development and production ! Cable fire paint color according to the provisions of GB / T 3181, and in accordance with user requirements determined in consultation

|